Homepsiadmin2025-04-07T13:27:18+00:00

1,500,000

Powering Forward

1,500,000

Engines Sold

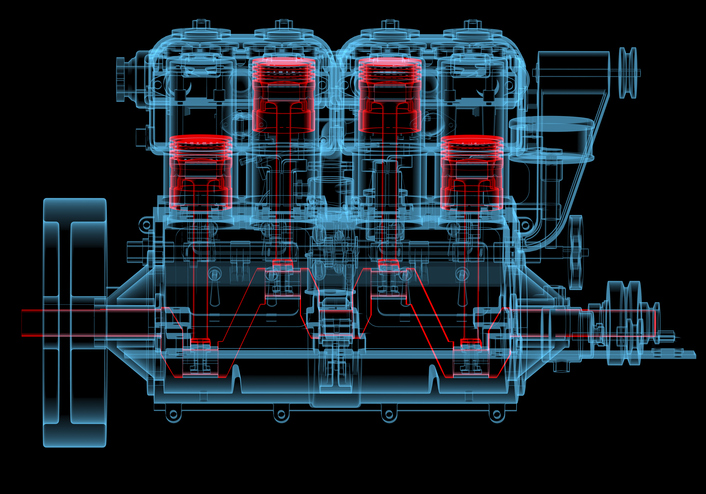

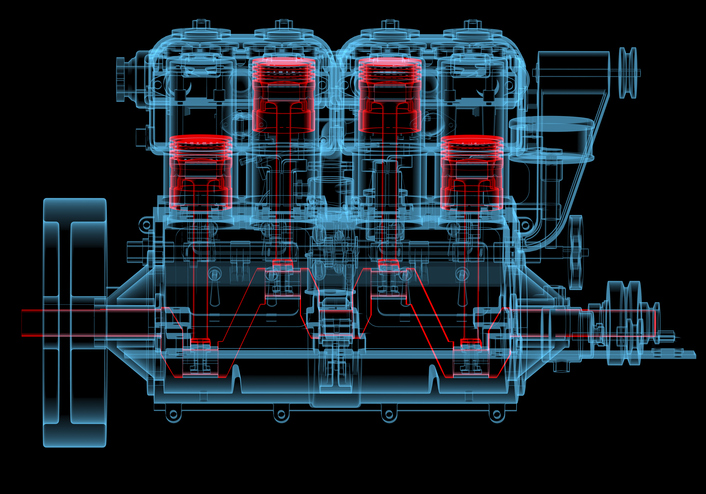

For more than 40 years, Power Solutions International has provided OEMs with powertrain products and solutions tailored for diverse needs. PSI has expertise developing, testing, integrating and manufacturing engines for a wide range of applications. PSI’s comprehensive engine portfolio includes displacements ranging from .97 liter to 88 liters, which run on a wide variety of fuels including natural gas, propane, gasoline, diesel and biofuels. From off-road and on-road industrial equipment to power generation, we can provide a fuel-flexible or fully electrified solution to your OEM’s needs.

Power Solutions

Explore our diverse range of robust, high-performance engine and powertrain solutions designed to meet the most demanding power needs across industries.