Engines

1.5M+

2024 Sales

$476M

Employees

800+

Square Feet

800k+

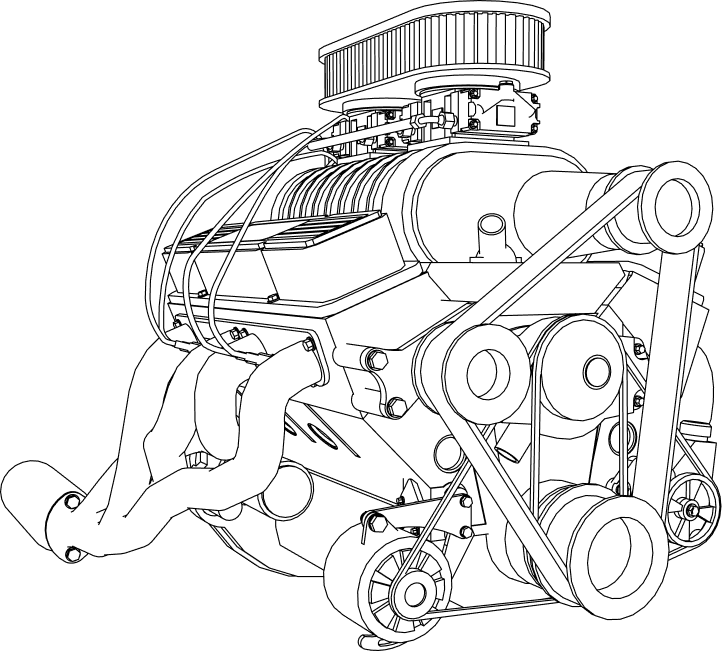

Power Solutions International, Inc. (PSI) is a leader in the design, engineering, and manufacture of a broad range of advanced, emission-certified engines, power systems, and accessories. PSI provides integrated turnkey solutions to leading global original equipment manufacturers and end-user customers within the power systems, industrial and transportation end markets. The Company’s unique in-house design, prototyping, engineering and testing capabilities allow PSI to customize clean, high-performance engines using a fuel agnostic strategy to run on a wide variety of fuels, including natural gas, propane, gasoline, diesel and biofuels.

PSI develops and delivers complete power systems that are used worldwide in stationary and mobile power generation applications supporting standby, prime, demand response and microgrid solutions, as well as products and packages supporting the rapidly growing data center markets.

PSI’s industrial segment provides engine and battery powertrain solutions to serve applications such as forklifts, agricultural and turf, arbor care, industrial sweepers, aerial lifts, irrigation pumps, ground support, construction equipment. PSI’s transportation segment provides engine powertrain solutions to specialized applications such as terminal tractors, port equipment, military vehicles, and other non-road vocational vehicles.

Our Facilities

Power Solutions International’s manufacturing facilities reflect our commitment to high-quality powertrains and technology. Our ISO-certified facilities are equipped with cutting-edge technology and utilize lean manufacturing methods, giving us the flexibility to meet high production demands in an efficient manner.

For more about our physical plants, click here.

Manufacturing Capabilities

PSI designs and manufactures engines that can meet specific requirements and provide power regardless of the conditions in which they operate.PSI’s manufacturing and engineering staff are experts in not only building engines, but also in understanding the specific applications they will power. We bring a vast amount of application design and design engineering experience to each application and provide a total value-added power solution to OEMs across several industries.

We offer a complete line of emission-certified industrial engines and serve as the Manufacturer of Record for all our engines. PSI assumes all legislative duties related to certification, enabling customers to focus solely on their products.

- CNC Machining

- Advanced applications engineering disciplines

- Material optimization and simulation

- Specialized manufacturing

- Calibration and emissions

- Electronics, software and controls

- Turbo and fuel systems

- Engine simulation, testing and validation

- Components and assembly

- Cooling package development

- Technical training programs